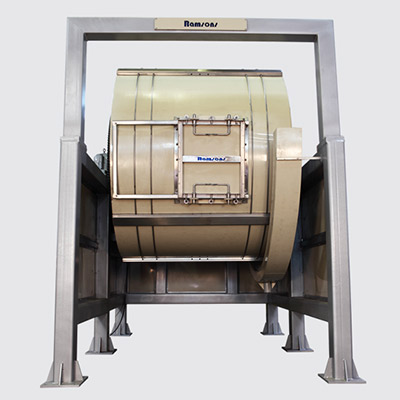

Material of manufacture: PP

PP make Rochling from Germany or Simona

Capacity: 750 Kg Wet Blue Loading.

- The PP drum is mounted on a heavy-duty Cast Iron Plumber block along with Bearing. Bearing Make: SKF or NTN.

- Drum Sides have Heavy duty Cast Iron molded machined hollow shaft and star (As a single unit).

- This entire assembly will be mounted on an RCC Civil Platform (This RCC Platform is within your scope as per drawing).

- This PP Drum is driven through a bevel helical Geared motor - Vertical Type (Make: SEW - EURODRIVE from Germany).

- The PP drum is provided with a smooth stainless steel 316 grade sliding door with silicon rubber Gasket, and all Fasteners are SS 316 G, and side star fixing bolts are High Tension TVS Make.

- The PP drum is also provided with a bunghole plunge to remove the process liquor, and the same is collected and diverted to the drain through the PP chute.

- This above machine is provided with a 400 ltrs cap. PP Chemical Feeding Tank with Stirrer Motor and dozing pump. (Cap: 1HP each)

- The total electrical control panel Box comes with electrical components like Relays, Contactor and Timers which are European Standard Brands. Inverter Drive also provided for the drum speed from 9 RPM to 14 RPM.

- The above electrical panel is provided with a total timer, Forward /Reverse Timer, Drum Up and Down inch switch and a small remote panel at the unloading point.